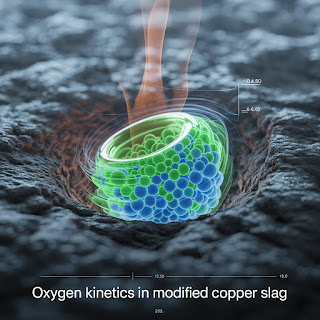

🌡️ Thermal and Metallurgical Analysis 🔬 Thermal and metallurgical analysis involves the study of materials under varying temperature conditions to understand their behavior, properties, and transformations 🛠️. This process is crucial in determining phase changes, thermal stability, and microstructural evolution in metals and alloys 🌟. Techniques like Differential Scanning Calorimetry (DSC) 🔥 and Thermogravimetric Analysis (TGA) ⚖️ measure heat flow and weight changes, while metallurgical methods such as Optical Microscopy 🔍 and Scanning Electron Microscopy (SEM) 📸 reveal grain structure and phase distribution. Applications include assessing weld quality for structural integrity 🏗️, optimizing heat treatment processes 🔧, and ensuring performance in extreme environments 🚀. By integrating thermal and metallurgical insights, engineers can design materials with superior mechanical properties 💪, corrosion resistance 🛡️, and longevity. This dual approach fosters innovation in i...